With this setup, it is a 2x10 speed drivetrain that covers a good range of gears, as shown below. With a standard crankset of 53/39T, and a close ratio 12-27T cassette, the gear steps between the gears are nice and close. As shown by the blue highlighted boxes, there are 13 unique gears with a gear range of 28.9" to 88.3". This is a good range that is suited to the riding usage of this folding bike.

2x10 speed gear ratios on the Dahon MuEX

On the Canyon Endurace road bike, it comes stock with an Ultegra 6800 11-32T 11 speed cassette, and I will be changing it to a Dura-Ace cassette. As such, I will have a 11-32T 11 speed cassette that I can either sell off or put onto another bike.

One idea that I have is to install this 11-32T 11 speed cassette onto the Dahon MuEX, and turn it into a 1x11 speed bike. There are many advantages to doing this, which I will list down later. The main problem with this idea is that the Kinetix Pro wheelset can only support up to 10 speed cassettes. A 11 speed compatible rear hub will need to have a freehub body that is longer by 1.85mm.

I really like the Kinetix Pro wheelset, therefore I am not willing to give up the wheelset to get a 11 speed rear wheel and drivetrain.

There is a new 11 speed road cassette that is compatible with 10 speed freehub bodies, and that is the Ultegra-level non-series cassette CS-HG800, with a wide 11-34T combination. The largest sprocket is offset inwards on the cassette spider, enabling an 11 speed gear spacing on a 10 speed freehub body. This concept is the same as on 11 speed Shimano MTB cassettes, where it can be used on standard 10 speed freehub bodies.

As this offset gear needs to have clearance with the hub flange and spokes, this offset concept can only be applied to larger sprockets, and in the case of CS-HG800, it is the 34T sprocket. Smaller sprocket sizes may hit the hub flange or spokes, depending on the hub design.

If I use this CS-HG800, it will fit directly on the Kinetix Pro wheelset, turning it into a 11 speed rear drivetrain. However, this will defeat the original purpose, which is to find a use for my 11-32T cassette from the Canyon Endurace.

Another problem that I have is with the gear ratios of the 11-34T cassette.

CS-HG800: 11-13-15-17-19-21-23-25-27-30-34

As shown here, there is a big jump from 11T to 13T. Although it is just a 2 tooth difference, the ratio difference is big due to the small gear size. On a MTB this is still acceptable, as there are big gear ratio differences all throughout the cassette and the riding style is different.

Gearing of CS-HG800 11 speed 11-34T cassette, with a big jump from the 13T to 11T.

However, this Dahon MuEX folding bike will be ridden mainly on the road, and so a big jump in gear ratio will not be suitable. As shown by the table above, the difference in Gear Inches from 13T to 11T is big at 18% and not comfortable for on road riding. My preferred gear combination would probably be something like this, with a maximum difference of 15%.

Preferred 11-34T: 11-12-13-14-16-18-20-23-26-30-34

Even if I wanted to use the CS-HG800 11-34T cassette, I would not have a compatible Di2 rear derailleur to use it with. The 11 speed Di2 rear derailleur that I have is the mid cage Ultegra Di2 RD-6870 which came stock on the Canyon Endurace. This rear derailleur can be used with a maximum sprocket size of 32T, which may still work with the 34T sprocket but is not ideal.

Therefore, I am in a dilemma. I have a 10 speed Kinetix Pro rear hub and a 11 speed 11-32T cassette which I want to use together. These two components are not compatible, unless one of them is modified. I have seen freehub bodies being modified to lengthen the spline section by 1.85mm, but this depends on whether there is actually extra space on the freehub body to allow this. In this case, there is no extra material on the freehub body where the splines can be lengthened by machining away part of the stopper.

No extra material on the freehub body flange that can allow the spline section to be lengthened.

In this case, if I want this to work, I have to find a way to reduce the length of the 11 speed cassette. Is there any possibility of machining away some material on the cassette, so that it can rest further on the freehub body?

There are a few areas that we need to check for clearance, if we want to make the cassette sit further inwards on the freehub body. Depending on the design of the hub and the cassette, these areas will vary, so it is only possible to check with the actual parts in hand.

Clearance between the rivet and the spokes is about 3mm, which is quite generous. Checked with a 3mm Allen key like a Go / No Go gauge.

Further in, there is also some clearance between the J-bend on the spoke and cassette spider. Probably about 2-3mm.

The design of this hub is such that the hub dust cap sits very close to the cassette spider. Only about 2mm of clearance between hub dust cap and cassette spider.

By placing the actual 11-32T cassette onto the freehub body of the Kinetix Pro rear wheel, I was able to check all the clearances. The limiting factor seems to be the clearance between the hub dust cap and the cassette spider, where there is a gap of only 2mm.

If the cassette is modified such that it sits the full 1.85mm inwards, then there will be too little margin and clearance. In this case, my estimate is that I can move the cassette inwards by a maximum of 1.5mm, leaving a small clearance of 0.5mm. This clearance is important during freewheeling, when the hub and cassette are rotating relative to each other.

If that is the case, the lockring engagement length will be reduced, from the nominal 1.85mm to about 1.5mm. Is this sufficient? Let's check.

I found that one sprocket thickness is about 1.6mm. By purposely leaving out one sprocket from the 11 speed cassette, and putting the rest of the cassette on the 10 speed rear hub, it simulates the condition where the cassette is moved inwards by 1.6mm (not the full 1.85mm). At this condition, I can check the lockring thread engagement and also the chain clearance with the inside of the dropout.

Simulating lockring engagement by removing one 1.6mm sprocket from the 11 speed cassette. There is also sufficient clearance between chain and dropout when using the 11T sprocket.

Since there is sufficient clearance, it seems that this project might work! The idea is to machine away some of the material on the spider of the 11 speed cassette, so that the whole cassette can sit further inwards on the freehub body. It will be a delicate balance between spoke clearance and also lockring engagement, as increasing one will decrease the other.

If the project is successful, the 11 speed cassette and Di2 RD on the Canyon will be transferred to the Dahon MuEX!

Diameter of flange on freehub body is about 40mm. The cassette spider needs to be larger than this diameter in order to rest further inwards.

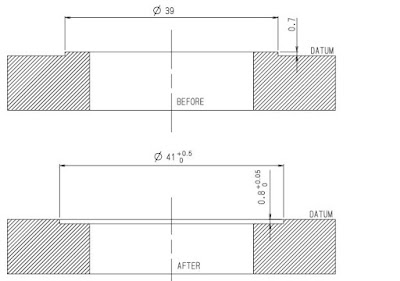

On the original cassette spider, there is a protruding step of about 0.7mm, with an outer diameter of about 39mm. This step needs to be removed and a larger counterbore made in order to fit over the flange of the freehub body.

With this engineering drawing, everything should be clear. From the condition on top (before), it needs to be modified to the dimensions below (after).

By removing the original 0.7mm protruding step, and adding a wider 0.8mm deep counterbore, the cassette will sit further inwards by a total of 1.5mm. What this means is that the clearance between the hub dust cap and the cassette spider will be only 0.5mm, while the lockring engagement is also compromised to be about 0.35mm less (1.85 - 1.5 = 0.35).

After machining the cassette spider according to the engineering drawing above, this is the final result. Strength does not seem to be an issue as there is still plenty of material around. Note that flatness is very important, so a lathe is required.

Diameter of the counterbore is more than 41mm, which is sufficient to clear the flange of the freehub body.

Just for reference, the weight has been reduced insignificantly from 280 grams before machining.

Clearance between spoke J-bend and cassette spider seems to be less than 1mm

Clearance between hub dust cap and cassette spider is also very small, at less than 1mm

With the final 11T sprocket yet to be put on, here is the engagement length available on the freehub body. Seems to be quite generous.

After putting on the 11T sprocket, it sticks out above the thread by 0.35mm more than the standard amount. The thread engagement length is thus 0.35mmm less but still looks sufficient.

By measuring the lockring, I found that the standard thread engagement length on the lockring is about 3mm, with a total of about 3 full threads. Since the thread engagement has been reduced by about 0.35mm, this means that there is about 10% less thread engagement. To me, this is still OK as it is not a large amount. As long as I don't over-tighten the lockring, the thread strength should be OK.

With that, this project can be deemed to be successful! I have managed to find a balance between spoke clearance and lockring thread engagement, enabling an 11 speed cassette to be installed on a 10 speed freehub body.

It goes without saying that this voids any warranty that you have on the cassette. It will not work in all cases, it really depends on the rear hub that you have and the cassette that you want to modify. For some rear hubs, it may be easier and more straightfoward to remove material from the freehub body instead of from the cassette spider. On other rear hubs, it may be impossible due to the hub design or insufficient spoke clearance.

11 speed 11-32T cassette installed on the 10 speed Kinetix Pro rear wheel!

This is the most challenging part of this project, to convert 2x10 speed to 1x11 speed on the 10 speed wheelset. Once this is done, the other components should not pose any problem. The rear derailleur and chain needs to be changed to 11 speed, and these components will also come from the Canyon Endurace.

The Di2 wiring will remain, as it is a simple matter of replacing the Di2 rear derailleur. As for the crankset, I will also bring over the Ultegra 6800 crankset from the Canyon Endurace, and convert it to a single chainring.

Depending on the chainring size that you choose, the gear range can be shifted higher for faster riding, or lower for climbing. It really depends on your riding style and fitness. However, the gear range itself cannot be widened or narrowed as it depends solely on the cassette size used.

In this case, using a 48T chainring, on this 20" 406 wheelset will give the gear range as shown in the table below. With a low gear of 30 gear inches and a high gear of 87.3 gear inches, it is almost the same as the previous 2x10 speed setup (28.9" to 88.3"). The difference is only an insignificant 1" loss at either end of the gear range.

New gear table with 11-32T 11 speed cassette and 48T chainring, on 20" wheels.

Some of you may think that a high gear of about 88" is too low for fast riding, but it is actually sufficient most of the time. For fast road riding with road bikes, this will not be sufficient. However, this is on the folding bike where high speeds are not necessary or feasible for me. As already tested on the 2x10 speed drivetrain, this gear range is sufficient.

Just for reference, the Java Freccia mini velo, which is a faster bike than this Dahon MuEX, also has a high gear of 88". If it is enough for the drop bar mini velo, it will be sufficient for this folding bike.

Although the gear range is maintained, it is now spread over 11 gears instead of over 13 gears. Theoretically speaking, the gear steps between gears will be larger. However in actual practice, this is not an issue as they are still close enough for comfortable road riding. If the 11-32T cassette is suitable for the road bike, it will definitely be OK for this folding bike.

If the gear range is maintained, with no other changes, then what is the purpose of going through all this trouble to change from a 2x10 to 1x11 speed drivetrain? What are the advantages?

1) Gear range is almost the same as before, but with less components.

2) Easier and less confusing gear shifting operation without left side shifter.

3) Lighter weight from removal of left side shifter, front derailleur and double chainrings, even though the larger cassette is slightly heavier.

4) Possibility of longer battery life as the rear derailleur consumes less power than the powerful front derailleur (my guess only).

5) Cleaner wiring setup with the removal of two wires (between left side shifter & display, and between Junction B & front derailleur).

This is a lengthy post, because I want to share the reasoning for changing the drivetrain on the Dahon MuEX folding bike from 2x10 speed to 1x11 speed. Also, modification of the 11 speed cassette to fit on the 10 speed freehub body was also not easy, with many checks necessary to ensure that this project has a high chance of success before making the modification.

It is not done yet! The Di2 rear derailleur and the single chainring crankset has not been installed yet, those will be covered in the next few blog posts.

You can just get an American classic 11sp freehub body and redish the wheel for this conversion. My Tern x20 now runs 2 x 11 ultegra. I got the AM freehub body from the Bike settlement in bugis area. Any wheelbuilder should be able to redish the wheel for u.

ReplyDeleteCheers and keep up the good work bro!

You can just get an American classic 11sp freehub body and redish the wheel for this conversion. My Tern x20 now runs 2 x 11 ultegra. I got the AM freehub body from the Bike settlement in bugis area. Any wheelbuilder should be able to redish the wheel for u.

ReplyDeleteCheers and keep up the good work bro!

Thanks for the info! Do you have any other specifications of this replacement freehub body? Will the hub end caps need to be replaced as well?

ReplyDeleteThe Tern kinetic pro x uses a A.M. RD205 rearhub. Strangely, this is cheaper locally than online stores. I searched for it in carousell and saw thebikesettlement selling for less than $90. Hopefully they still have stock. Simple job to switch freehub bodies but Redishing is a must after installing the new 11sp freehub. Nothing else needs to be changed.

ReplyDeleteCheers

Thanks for the info. Just wondering about the design. Did you have to change the left or right side end caps too? Else you can't just add 1.85mm to the right side without reducing it somewhere else...

DeleteI din change anything except the freehub and getting it redished.

DeleteIn fact when I started doing this upgrade, I did not know the freehub is not for 11sp. However an ultegra 6800 Cassette will fit into the freehub body and secure with lockring. However the lockring will rub against the frame. I did contemplate changing a slimmer lockring or changing end caps but I chanced upon the 11sp freehub body in carousell and went that direction instead. I reckon that should be the “correct/pro” way of doing this upgrade.

Hope this helps.

Cheers

The freehub body design is slightly different. It will add some width to drive side but is not a full 1.85mm. That’s why I say redishing is a must after changing freehub. This is to offset the additional width on drive side.

DeleteRegarding this article: https://handsonbike.blogspot.com/2017/12/dahon-muex-1x11-drivetrain-11-speed.html

ReplyDeleteI realize that I'm late to the party, but Sunrace now offers 11-speed wide-ratio road cassettes (http://www.sunrace.com/en/products/detail/csrx8).

I used SLX cage plates to make a long cage 105 derailleur for my dyslexic daughter's bike so that I could get her down to one shifter. The SLX cage also moved the upper jockey wheel further away from the cassette, which gave me the room that I needed for the 42t cog without using a derailleur extender.

As with all bikes, your mileage may vary because of both the placement of your derailleur mounting point and the design of the rear dropout on your bike.

This comment has been removed by the author.

ReplyDelete