With much effort, the modification of the Fnhon folding bike has been completed! Since it has been converted from 11 speed to 12 speed, the name will change accordingly to Fnhon DB12.

Check out the previous posts for all the parts that are necessary to make this modification. For this post, I shall let the pictures do most of the talking instead of writing too much.

Full 1x12 speed setup completed! Minimal wire/cable routing, with only brake hoses required.

Unholy alliance of SRAM AXS drivetrain parts with an Ultegra 6800 crankarm.

Wolf Tooth 44T chain ring that is compatible to the SRAM 12 speed Flattop chain

Flattop chain gives a distinctive look to the drivetrain, this can be spotted from far away.

Heart of the SRAM AXS system! The 12 speed cassette and the Force AXS 12 speed wireless rear derailleur.

Force 10-36T 12 speed cassette, mounted on the XDR freehub body.

As mentioned in the earlier post, I made the chain as long as possible, without going slack in the smallest sprocket. This is opposite to the official recommendation, where the chain is made as short as possible, without over-stretching the rear derailleur in the largest sprocket.

My intention of using a longer chain is to reduce the amount of tension on the rear derailleur cage, especially in the lower gears. There are pros and cons to this approach, which I will explain using the pictures below.

This is the rear derailleur in the top gear (smallest 10T sprocket). The chain is sized such that it just puts a bit of tension on the rear derailleur cage, without the chain going slack.

There is minimum chain tension and rear derailleur cage tension at this gear, which can lead to chain slap when riding on uneven terrain. This is where the clutch is supposed to do its job to minimize chain slap.

The rear derailleur sticks out quite a lot from the frame, unlike the Shimano shadow type rear derailleur where it is a lot closer to the frame.

At the lowest gear (largest 36T sprocket), the chain tension and rear derailleur cage tension does not go too high, as the cage is not stretched till it is almost straight.

Still a healthy clearance between the rear derailleur cage and the wheelset rim.

Pros of using a long chain:

1) Less chain tension can improve shifting performance.

2) Less rear derailleur cage tension means improved cage spring durability.

Cons of using a long chain:

1) With a lower chain and cage tension, the rear derailleur cage tends to bounce more when riding over uneven ground. This can be mitigated if your rear derailleur has a clutch.

2) Slightly more weight.

Pros of using a short chain:

1) Higher chain and cage tension can help to reduce chain slap.

2) Slightly lower weight.

Cons of using a short chain:

1) High chain tension can cause poorer shifting performance.

2) High cage tension can cause reduced cage spring durability.

Both ways will work fine, it is just that I usually prefer the long chain method for a front single drivetrain, where it is possible due to excess chain capacity (without front double chain ring).

Next, I will move on to the handlebar side, where the sole highlight is the new GX AXS wireless shifter. All other components such as the XTR brake levers and Ergon grips remain the same.

Final position of the shifter, after making a few adjustments to find the optimum position with good ergonomics.

Just a pod hanging off the brake lever clamp band, without any wire or cable coming out of it.

From the rider's point of view. I like how it looks with just two clamp bands, with no wires running around.

Looks good from the front as well, with just two brake levers and two hydraulic hoses visible.

Again, another unholy alliance where the SRAM shifter is attached to the Shimano brake lever with a third-party adapter.

Final bike specifications and weight! It actually gained about 70 grams over the previous version, mainly due to the heavier saddle, rear derailleur and bottom bracket.

The weight comparison is not entirely fair, as I changed other items at the same time, along with the 12 speed components.

For example, the non-related components that I also changed are the bottom bracket (+35 grams) and saddle (+65 grams). This contributed to a 100 gram increase, which is not related to the 11 to 12 speed change.

Therefore, if we exclude this non-related 100 grams, changing from the previous 11 speed Di2 setup to this 12 speed AXS setup saves about 30 grams. I would say there is no significant increase or decrease in weight from this modification.

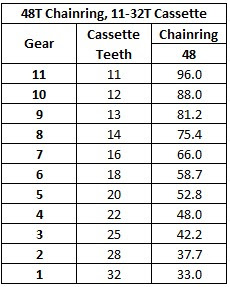

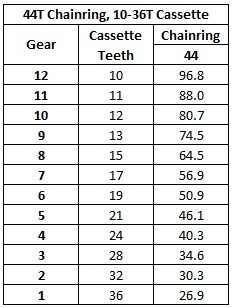

Lowest gear ratio of 27 gear inches makes it easier to climb Lorong Sesuai.

Extended testing on the Green Corridor.

Went all the way to Peirce Reservoir for slope testing!

Here is a good look at the 1x12 speed drivetrain. Rear triangle looks very neat without any wires or cables.

The Flattop chain really gives the drivetrain a distinctive look. From far, I can see that this is a AXS 12 speed drivetrain, just by looking at the chain.

I am quite happy with this successful modification, as I have managed to increase the gear range, while tidying up the bike with no cables or Di2 wires. The overall weight difference is negligible as well. Most important of all, I have learnt quite a lot from this modification, as I was not familiar with the SRAM AXS system.

However, the downside of this SRAM AXS modification is poorer shifting performance, compared to the Shimano Di2 drivetrain. There are occasional mis-shifts at the smaller sprockets, which I am unable to resolve even with rear derailleur adjustments. Solving the mis-shift issue at some gears would cause other gears to develop noise or mis-shifts instead.

On the other hand, the shifting performance at the lower gears (larger sprockets) are very smooth. In fact, sometimes it is so smooth that I cannot feel the gear change from the pedals! The lack of a gear indicator or display also forces me to look down at the cassette often to know which gear I am in. On the previous Di2 system, the Di2 display would show the gear number, and also emit a beep sound when I am at the extreme gears (1st or 11th gear)

Finally, there is more driving noise and chain vibration that can be felt through the chain and pedals, especially in the smaller sprockets.

That said, I don't regret changing to this AXS wireless system. It is something that is unique and good to try.