Building up a frameset from scratch is always challenging, as each bike frame has its own quirks and requirements. I always learn new things when building a new bike, which is interesting and also challenging.

This time, I built a Focus Paralane, to use as my all-weather commuting bike. One major reason I chose this bike was the presence of proper mudguard mounts. Besides, it has a normal road bike geometry, instead of a more upright hybrid bike geometry. Lastly, it has a lightweight frameset that is hard to find, in combination with the other two factors listed here.

Interesting parts of this bike are the new Brand-X carbon handlebars, Shimano 105 R7000 4iiii Power Meter, Shimano RS770 wheelset, and other parts of the drivetrain as shown here.

Here is the bare bike, without any accessories. Looks just like a normal road bike!

Using PRO handlebar tape, which is cheap and good. I used to like Lizard Skins bar tape, but they start peeling far too quickly and easily.

Wrapping the handlebars with bar tape, once the shifter positions have been tested and fixed.

Making the cockpit look neat

Here is how it looks with the mudguards installed. At this point it is ready for wet weather riding!

Unfortunately the setback seatpost is still in use at this point in time, due to the lack of good 25.4 mm diameter alternatives.

Normally I would not ride the bike without other accessories such as lights, tools, water bottle, etc. Therefore, my actual bike weight during usage is always higher than the bare bike weight. How much weight do I add onto my bike, when I attach all the accessories?

1 kg is added to the bike, when I include all the accessories such as tool bottle (with tools), lights, bottle cages, lights, cycle computer, bell, etc.

Added the Garmin outfront mount and the Edge 530 head unit, the Quad Lock mount, and the Spurcycle bell.

Cycliq Fly 6 CE rear light + camera, spare D-Light rear light, Lezyne portable pump, tool bottle and water bottle added too.

Complete with all the accessories! Now it looks more like a commuter bike...

It doesn't look as sleek after adding all the accessories, but they are considered essential for safe and practical commuting.

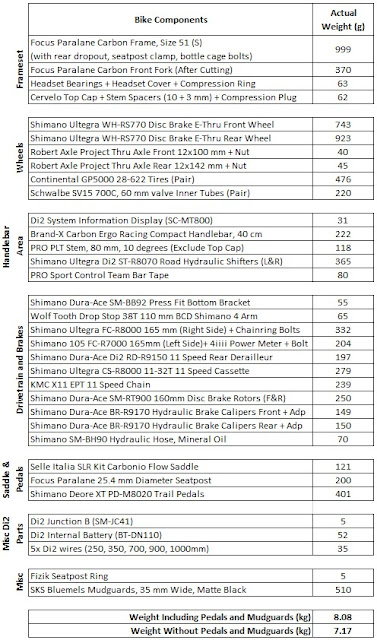

Here is the actual part list and weight as shown, without accessories. Add 1 kg if accessories are included.

If I use it as a pure road bike, without mudguards and accessories, it actually weighs just 7.2 kg without pedals. It is a very good weight, compared to my previous Canyon Endurace and the current Cervelo Aspero.

My pedals usually weigh close to 400 grams, as I use SPD pedals. The mudguards add about 500 grams to the bike, which is quite substantial.

If compared to my previous Fabike C3 commuting bike, there is a huge difference of 1.9 kg!

Road bike spec, without pedals:

Focus Paralane: 7.2 kg

Overall I am happy with the substantial weight reduction over the previous Fabike C3. Not only is it now lighter in weight, the drivetrain is also more efficient, which means that it rides even more like a proper road bike. I have achieved my objective to have an all-weather road bike!

I no longer have to choose between my Fabike C3 (good for wet weather, but heavier and slower), or the Cervelo Aspero (lighter and faster, but cannot handle wet weather) when commuting. Now, the Focus Paralane is lighter, faster, and yet also all-weather capable. Basically I can use this bike for my commute 100% of the time, without any compromises.