Standard bike wheels will not do the job, as they are not designed for heavier loads, therefore we need to look for a set of durable wheels. BMX wheels have stronger rims and many more spokes, due to the high loads exerted on the wheels when jumping off ledges or doing tricks. However, standard BMX wheels cannot support an 11 speed cassette as the hub is usually limited to single speed gears.

Since I want to run an 11 speed cassette on the cargo bike, I have to get a custom built wheelset that can support an 11 speed cassette, with strong rims and more spokes.

Ascent Bikes allow lots of customization of their bikes and wheels, and you can pretty much specify any component you want on the bike, down to the colour of the bolts or the type of stickers on the wheels. Still, this request for a custom built, extra strong wheelset is not common, but they are willing to help me out with this.

My request is quite straightforward. To have a 20" wheelset with 32 or 36 spokes, using a hub with 100/135 mm OLD, and compatible with Centerlock brake rotors. It should be all black in colour (rims, hubs, spokes, spoke nipples) for a clean appearance.

For the rims, 20" BMX rims were used, as they are strong and wide enough, and comes in 36 hole variants. Straight gauge 2.0 mm spokes and brass nipples were used for strength, no lightweight aluminium spoke nipples here. Finally, the request for a Centerlock brake rotor compatible hub pretty much limits the choice of hubs, and the dependable Deore XT M8000 hubs were chosen.

All black wheelset! Lots of spokes for extra strength and rigidity.

Deore XT M8000 hubs with Centerlock brake rotor mounting.

Extra wide BMX rims

Black brass spoke nipples

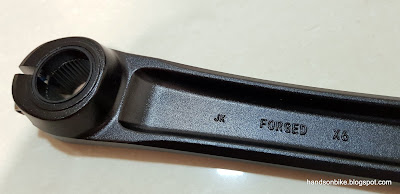

2.0 mm straight gauge spokes used for extra strength.

Rim height is about 17 mm, with no rim brake track.

Internal rim width is 24 mm, which is really wide.

External rim width is 29 mm. This also means that any tire that I install on these rims will end up being wider than the nominal claimed width.

Includes high quality, wide Schwalbe rim tape.

Front wheel weighs 703 grams (including rim tape).

Rear wheel weighs 866 grams (including rim tape).

The total wheelset weight, inclusive of rim tape, is 1569 grams. This is actually lighter than I expected (1.7 - 1.8 kg), which is awesome. In fact, it is lighter than the stock Dahon D7 wheelset that comes with the Dahon Boardwalk, but is much stronger.

Deore XT QR axles, which are heavy but strong. Not a place to compromise on strength for a cargo bike.

With the custom built, heavy duty wheelset ready, the next important choice is the type of tires. The tires also have to be strong enough to withstand the additional weight of a cargo bike, so lightweight, narrow tires are out of the question. Which leaves us with tougher, wider but also heavier touring tires. There are quite a few different types of touring tires, which makes it difficult to choose.

In the end, I chose the narrowest, lightest touring tire that I think I can get away with, and that is the Schwalbe Marathon. Taking into account the permissible load on each tire, the type of tread pattern (smoother for lower rolling resistance), and the puncture resistance, this was the choice. The standard Marathon does not have very high puncture resistance (like the Marathon Plus), but it is much lighter and rolls better, and it is a risk that I am willing to trade off. No matter what, it will be more puncture resistant than the tires on my other bikes.

Pair of Schwalbe Marathon tires! Equipped with reflective strips for additional visibility at night.

Closer look at the logo and model name.

This is the narrower variant, at just 1.5 inches wide. It would prove to be the correct choice, as shown later when installing the rear derailleur and cassette. The E-Bike ready label doesn't mean much here.

Rather deep treads, for extra grip over rough and loose terrain. The centre line has a continuous unbroken surface, which should mean lower rolling resistance and lower noise.

Recommended tire pressure is a wide range, from 55-100 PSI. For heavier loads, it is recommended to set the pressure at the higher end of the range for less chance of a pinch flat.

Each tire weighs 557 grams, a far cry from the 239 grams for Schwalbe Kojak tires. The heavier duty Schwalbe Marathon Plus tires are even heavier!

As for inner tubes, the 40-406 tire size is in-between inner tube sizes. Either SV6 or SV7 tubes can be used.

In the end, I chose the wider but heavier SV7 inner tubes, as the wider rims mean that the tire would end up being wider than 40-406.

Tires and inner tubes installed on the wheelset!

This wheelset looks strong and durable, ready to be installed on the cargo bike! At that time, I was still waiting for the frameset, and started gathering all the necessary components for the bike.