Continuing from the bike fitting session at Loue Bicycles, another area that was adjusted was the height of the cleats.

Other than shifting the cleats rearwards by about 20 mm, Timothy also added a shim on the left side SPD cleat. Due to the body asymmetry described in the previous post, the saddle height was finally set to be optimum based on my right leg, but this means that the saddle height is slightly too high for my left leg.

Therefore, to compensate for this, a cleat shim was added under the left side SPD cleat, in order to effectively lengthen the left leg slightly.

Plastic SPD cleat shims added temporarily by Timothy. By stacking 2 pieces, it effectively adds about 1.5 mm of height.

The plastic shims are just a temporary measure, as they do not last long. He recommended that I get the Crankbrothers shoe shields, which are metal shims that will work better.

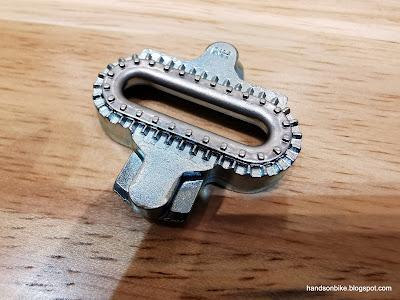

Crankbrothers shoe shields!

These are actually to protect carbon soles on the shoes, or to push out the cleats on shoes where the tread protrudes too much.

The shoe shields go between the cleat and shoe.

Each pack comes with 2, for a pair of shoes.

The knurled surface on the stainless steel plates will be on the side of the shoe.

Each shim has a thickness of 0.8 mm.

I plan to use 2 shims, to get a thickness of 1.6 mm, which is close to the 1.5 mm suggested by Timothy.

However, 2 shims is too much, as the cleat bolts are not long enough to engage the thread properly.

In the end I only added 1 shim, under the left cleat to increase the height by 0.8 mm.

However, this additional 0.8 mm shim made the cleat protrude above the treads of the shoe, as you can see on the right side of the picture.

After I already bought the cleat shims, I realized that SPD cleats sometimes come with its own shim, I had forgotten about that. This is how it looks like.

This fits onto the SPD cleat and adds about 1 mm of thickness. It is usually used for non-Shimano shoes where the sole treads may be too tall for easy pedal engagement.

Same here, the shim makes the cleat protrude from the sole treads.

Although the taller cleat is necessary to compensate for the leg length, the cleat keeps touching the ground when I walk, since it protrudes too much. It is very annoying as I can feel the metal cleat clicking on the hard ground, and it is also slippery due to the metal cleat surface.

I will have to think of an alternative solution as the protruding cleat is not acceptable for me.

A side effect of moving the cleat rearwards, is that the shoe is effectively moved forward. This leads to shoe interference with the front wheel during cornering. As the Focus Paralane already has mudguards, which were already touching the shoe previously, this cleat adjustment made it even worse.

Interference between the shoe and the front wheel/mudguards during cornering.

Due to this phenomenon, I have to be extra careful during cornering, so that the shoe is not pointed forward where it can touch the mudguards. It is avoidable with careful placement of the pedal position during cornering (outside shoe downwards, inside shoe upwards).

In summary, the cleat shims can effectively extend the leg reach, but it causes another problem where the metal cleat keeps touching the ground during walking. I have an idea to solve this, which will be shared in the next post.

Does this issue with touching the wheel with your foot mean your bike size is a tad too small?

ReplyDeleteIt's not too small, as the stack and reach of the bike frame is correct. Just that I added mudguards which reduces the clearance. I think most road bikes will face the same issue.

Delete